Our Workshop

Room 612

After 10 years of working in student garages every FRC season, the Fremont Union High School District and Lynbrook High School’s administration finally gave Team 846 a classroom to use as a workshop on the edge of the campus in 2011. This space currently contains various machinery and equipment used in building the robot, which would not have been possible before. The Funky Monkeys are grateful to have a permanent home at Lynbrook High School!

See the 360 view of our workshop by Hanzen Shou !

360view by Hanzen Shou on Sketchfab

Our Machines

CNC

The moment you set foot in the machine shop, you notice two very large machines: our Tormach PCNC 1100s. Our two CNC Mills, named Han and Chewie, are the highlights of our machine shop. With Computer Aided Machining software, students can convert a solid model into a set of instructions and machine parts to incredible tolerances. Since 2012, the Tormachs have enabled students to design and create many complex parts, from gearbox plates to custom-made drivetrains. Students operate the CNC daily during build season, keeping an attentive eye on the monitor running the GCode and the tool spinning in the spindle and precisely carving out the aluminum. With the CNC, the team manufactures all parts on the robot in-house. Newcomers may be startled by the pervasive smell of machine coolant for the CNCs, but after a season in the shop, students grow to miss it.

Bandsaw

The machining process almost always starts with the use of the bandsaw. Students use the bandsaw to cut raw material into more manageable rough outlines. Vertical band saws are specially designed to effectively cut a variety of materials, such as aluminum, polycarbonate, delron, and wood. With a little bit of training, students become capable of contour cutting, straight cutting and re-sawing, and can cut delicate curves in both thick and thin material.

Lathe

Equipped with a digital readout displaying the coordinates of the cutting tool, the lathe can be used to cut parts with precision down to a few hundred millionths of an inch. The lathe is capable of not only churning out spacers and standoffs, but also making complex modifications like e-clip grooves to motor and gearbox shafts.

Drill Press

The drill press provides quick machining for prototyping and finishing parts. Students use the press to drill different sized holes into parts made of materials like aluminum and wood. We use the drill press the most when making our various prototypes; its efficiency allows for quick iterations without much calibration. After students finish a part, the drill press also allows for quick and safe deburring of holes with a countersink.

Mini Mill

In our fall workshop series, the students are introduced to machining with the Mini Mills. They learn to create the parts to specifications by manually adjusting the table of the mini mill back and forth, left and right. Once build season starts, the mini mills become the most often used machines in the shop. From brackets and connectors to bars and C-Channels, students create a variety of parts using the mini mills.

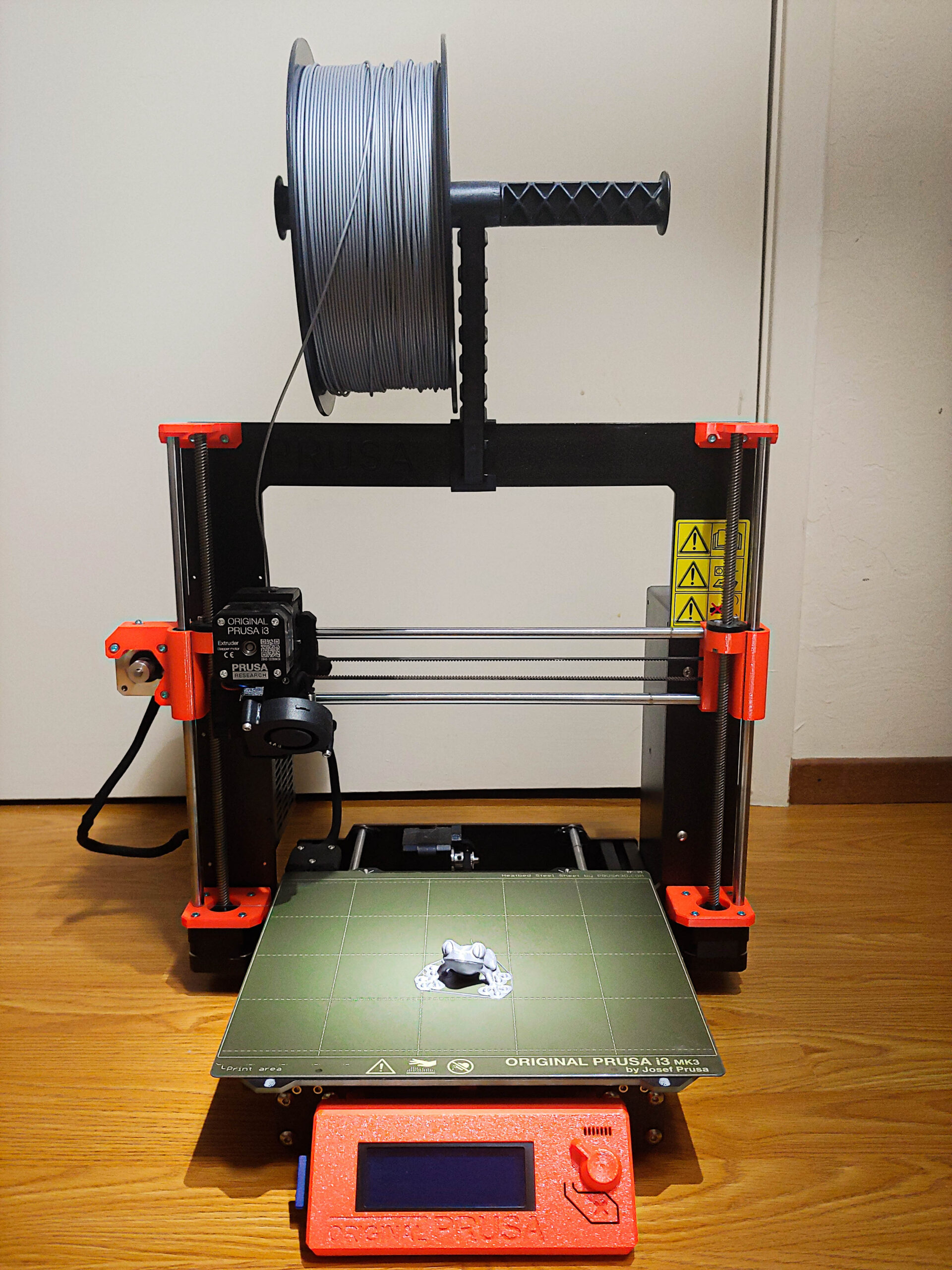

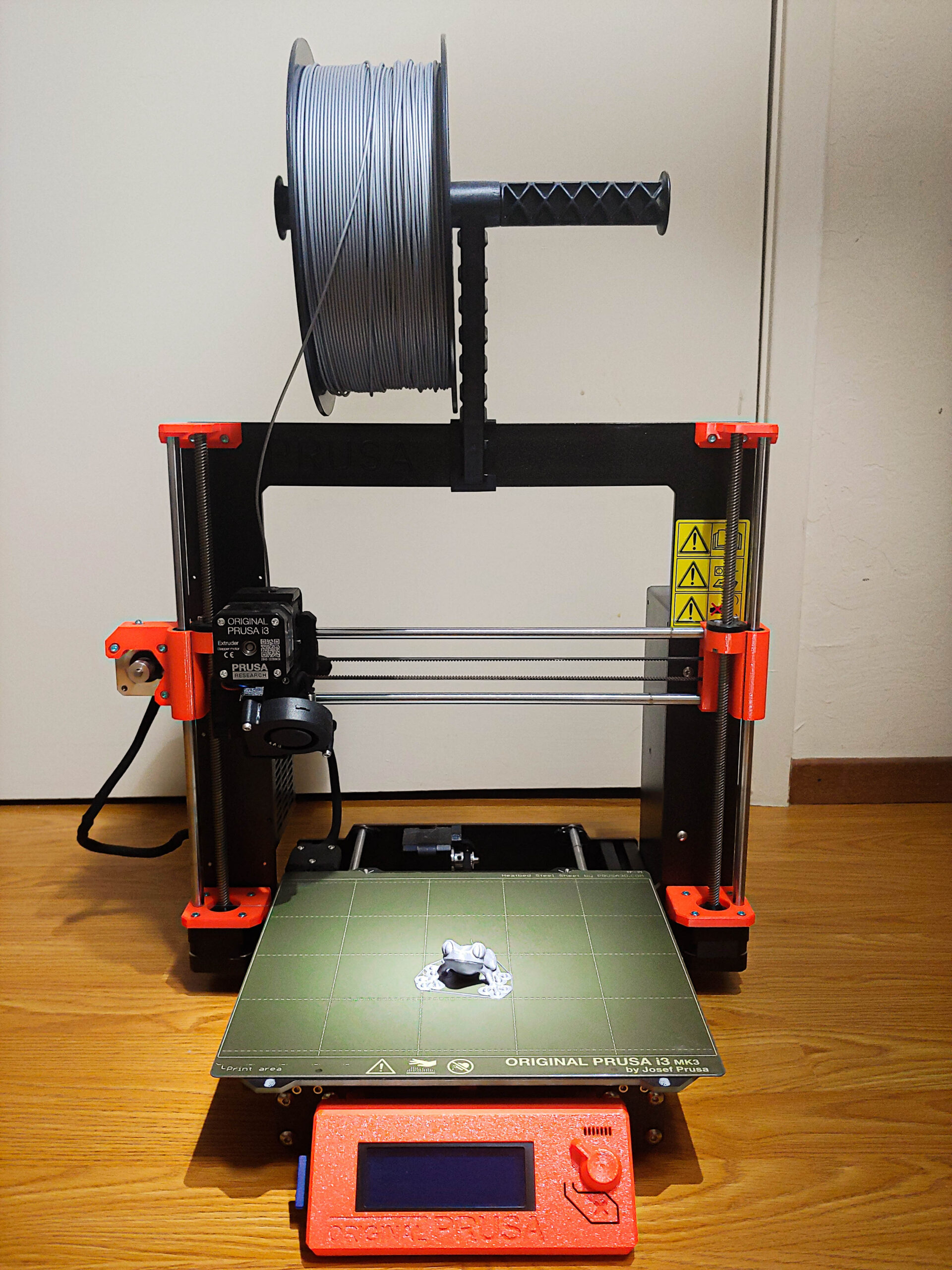

3D Printers

3D printers are used to print custom parts for the robot. In the past, students have printed mecanum wheels, ear savers for face masks, and even miniatures of the robot! The printer melts the filament through a nozzle onto a heated bed. The bed and the nozzle move to so that the filament forms a shape. This process is repeated to form layers. Our team uses the Prusa i3 and the Monoprice Select Mini V2.